Eternus Performance Materials is one of the leading companies in India, engaged in high-end research and manufacturing of Advanced Composite Products. It focuses on Aerospace, Space Exploration, Medical and Bespoke Luxury Products sectors.

It undertakes exclusive projects in design, development, prototyping and commercial batch quantity manufacturing.

Eternus specializes in design and manufacturing of critical, complex and difficult to realize products. Products having very stiff tolerances on strength, overall weight and distribution of weight across the laminate, fiber volumes, void content etc. – are our forte.

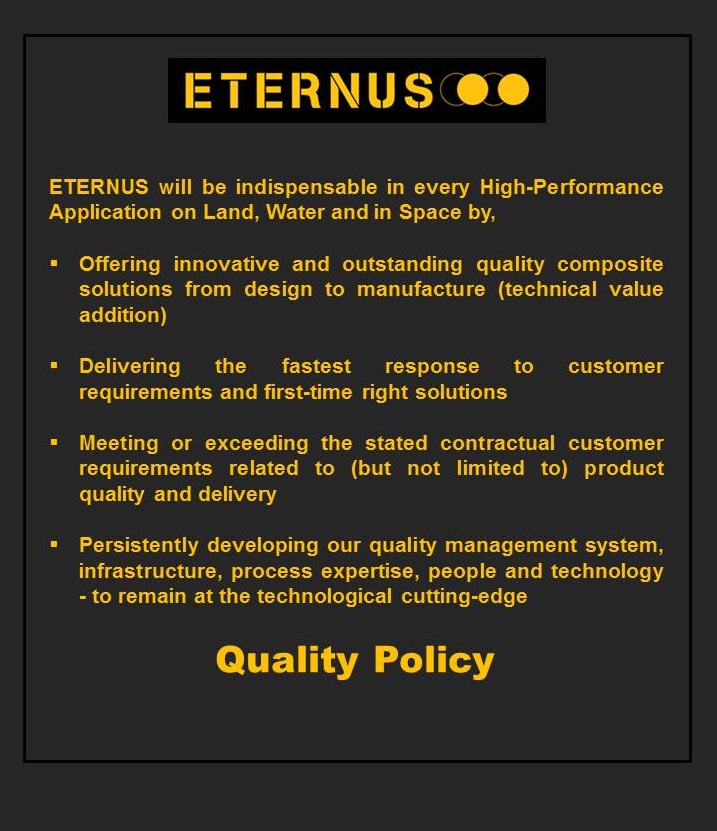

Our Quality Policy guides us in everything we do.